Lightning Protection System (LPS)

A Lightning Protection System (LPS) is designed to protect buildings, structures, and their contents from the destructive effects of lightning strikes. These systems prevent damage by safely directing the electrical energy from a lightning strike into the ground, thereby minimizing the risk of fire, electrical surges, or structural damage.

Key Components of a Lightning Protection System (LPS)

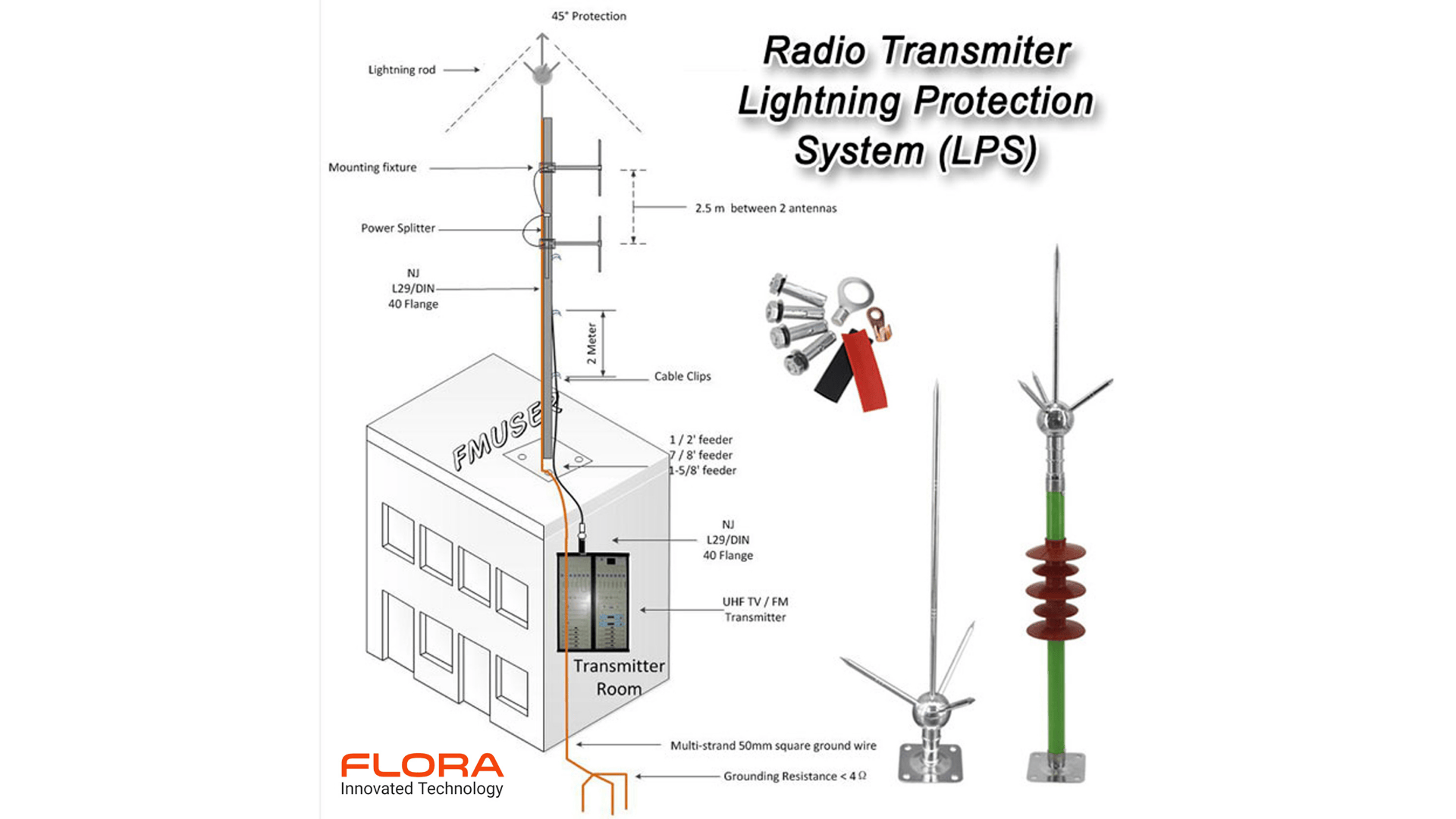

- Air Terminals (Lightning Rods)

- These are metal rods placed at the highest point of a structure, such as a roof, to intercept a lightning strike.

- The role of the lightning rod is to provide a preferential path for the lightning to travel through the system safely to the ground.

- Conductors

- These are copper or aluminum cables that connect the air terminals (lightning rods) to the grounding system.

- Conductors are installed along the building’s exterior, running from the lightning rods down to the ground, ensuring that the lightning energy is transferred efficiently.

- Grounding System

- The grounding system provides a path for the lightning energy to be dissipated safely into the earth.

- This system typically consists of metal rods or plates (ground rods) that are buried deep underground to ensure proper dissipation of the electrical charge.

- A good grounding system is crucial for the effective performance of an LPS. Without proper grounding, the lightning strike might cause significant damage to the structure.

- Bonding (Equipotential Bonding)

- Bonding involves connecting all metallic parts of the building (e.g., plumbing, electrical systems, and steel reinforcements) to the LPS.

- This ensures that in the event of a lightning strike, all parts of the building are at the same electrical potential, preventing dangerous electrical differences that could lead to sparks or fires.

- Down Conductors

- These are the conductors that carry the current from the lightning rod to the ground.

- They should be installed vertically down the exterior of the building and, in some cases, hidden inside the building.

- Surge Protection Devices (SPDs)

- These devices are installed in electrical systems to protect sensitive electronics and equipment from the surges caused by nearby lightning strikes.

- Surge protectors work by redirecting excess voltage away from the electrical circuits and into the ground, thereby preventing damage to appliances and systems.

- Earthing (or Grounding) of Electrical Equipment

- The earthing or grounding of electrical appliances, distribution panels, and other electrical systems is essential to prevent equipment damage or fire due to electrical surges from lightning.

Design and Installation Considerations

Designing and installing a proper lightning protection system requires a comprehensive assessment of the structure, including:

- Building Type and Location

- High-rise buildings, towers, or structures located in areas with frequent thunderstorms are more likely to require a robust LPS.

- The location of the structure (e.g., coastal, mountainous, etc.) and the local lightning strike frequency should be considered to determine the scale of the LPS.

- Risk Assessment

- A risk assessment is crucial in determining the need for an LPS. This includes considering the potential for lightning strikes, the value of the property, and the consequences of lightning damage (e.g., loss of life, injury, or fire).

- Compliance with Standards

- Various standards and regulations govern the design and installation of LPS. Some widely recognized standards include:

- IEC 62305 (International standard for lightning protection)

- NFPA 780 (National Fire Protection Association standard in the U.S.)

- BS 6651 (British Standard for lightning protection systems)

- Various standards and regulations govern the design and installation of LPS. Some widely recognized standards include:

- Installation and Maintenance

- Proper installation by certified professionals is necessary to ensure the effectiveness of the system. Incorrect installation can render the system ineffective.

- Regular maintenance checks, such as inspecting conductors for wear or corrosion, testing grounding resistance, and checking surge protection devices, are critical to ensure continued protection.

Types of Lightning Protection Systems

- Conventional Air Terminals (Franklin Rod System)

- The classic “lightning rod” system, where one or more air terminals are installed at the highest points of the building. This system captures the lightning strike and conducts it safely to the ground.

- Early Streamer Emission (ESE) Systems

- These systems use an advanced lightning rod that emits a controlled electrical discharge before the lightning strike occurs. The goal is to attract the lightning strike earlier and control its path.

- ESE systems are especially useful in protecting larger buildings or more complex structures.

- Faraday Cage (Mesh System)

- This type of system creates a continuous conductive mesh (often made of copper or aluminum) around the entire structure, including the roof, to shield it from lightning.

- The mesh conducts any lightning strikes safely to the ground and is especially useful in protecting sensitive electronic equipment.

Benefits of a Lightning Protection System

- Prevention of Fires: Lightning strikes can ignite fires, especially in buildings with flammable materials. An LPS helps to direct the strike’s energy safely into the ground, reducing the risk of fire.

- Protection of Electrical Equipment: Lightning-induced surges can damage electrical systems and sensitive equipment. Surge protectors, installed as part of the LPS, shield electronic devices from these surges.

- Reduced Risk of Structural Damage: Lightning strikes can cause extensive damage to a building’s structure. By providing a clear path for the lightning to follow, an LPS minimizes the risk of physical damage.

- Increased Safety: The primary benefit of an LPS is safety. It protects people inside the building by reducing the risk of electrical shock from a lightning strike.

- Insurance Benefits: Having a properly installed and maintained LPS may reduce the cost of insurance premiums, as the risk of damage from lightning strikes is significantly lower.

Maintenance and Testing of a Lightning Protection System

Regular maintenance and testing are crucial for ensuring the long-term effectiveness of a Lightning Protection System (LPS). Some of the key aspects to monitor include:

- Visual Inspections: Check for visible damage to conductors, air terminals, and grounding connections, as well as corrosion or wear.

- Testing Ground Resistance: The grounding system should be tested periodically to ensure that the resistance is within acceptable limits (typically less than 10 ohms).

- Surge Protector Inspections: Test surge protection devices to ensure they are functioning correctly and replace them if necessary.

- System Integrity Checks: Ensure all components of the LPS are intact and that there are no loose connections or degradation that could impact performance.

Modern Developments in Lightning Protection

- Smart Lightning Protection: With the advent of smart building technologies, some modern LPS systems are now integrated with IoT (Internet of Things) devices. These systems can monitor and report the condition of the LPS in real-time, alerting building managers to potential issues.

- Advanced Materials: The use of new materials like carbon nanotubes and graphene in lightning protection systems may improve their performance and reduce the weight and size of components.

- Drone Inspections: Drones are being used for aerial inspections of large-scale lightning protection systems, especially on high-rise buildings and towers. They can quickly and safely detect potential issues without the need for scaffolding or ladders.